Release time:2023-04-24 09:24:00 Viewed:0

1. Test content and requirements

Detection of workpiece area:

Area test of hexagonal screw head with width of 17mm and sample with height of 21mm

Test contents:

1: Head surface scratch is detected on the bottom surface

2: Side detection of height, screw presence and number

3: Top detection screw front end damage

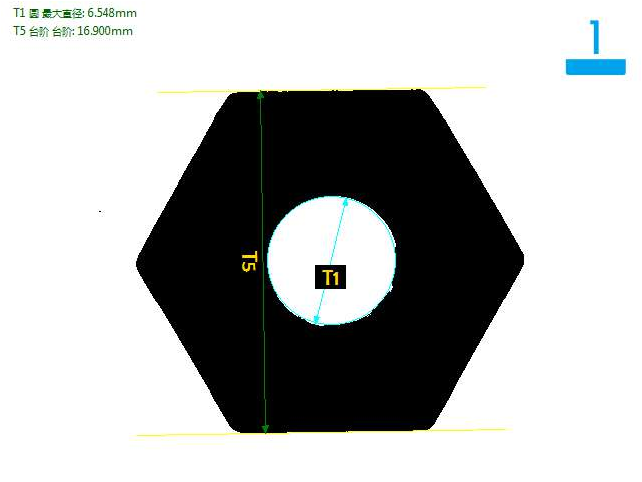

4: The backlight detects the diameter of the inner hole and the width of the head

Note: The above test items, all need to be clearly visible under the image to detect

Detection efficiency: 100-300 pieces per minute (according to the sample feeding speed).

Division of work: subdivide the detection steps according to the detection content.

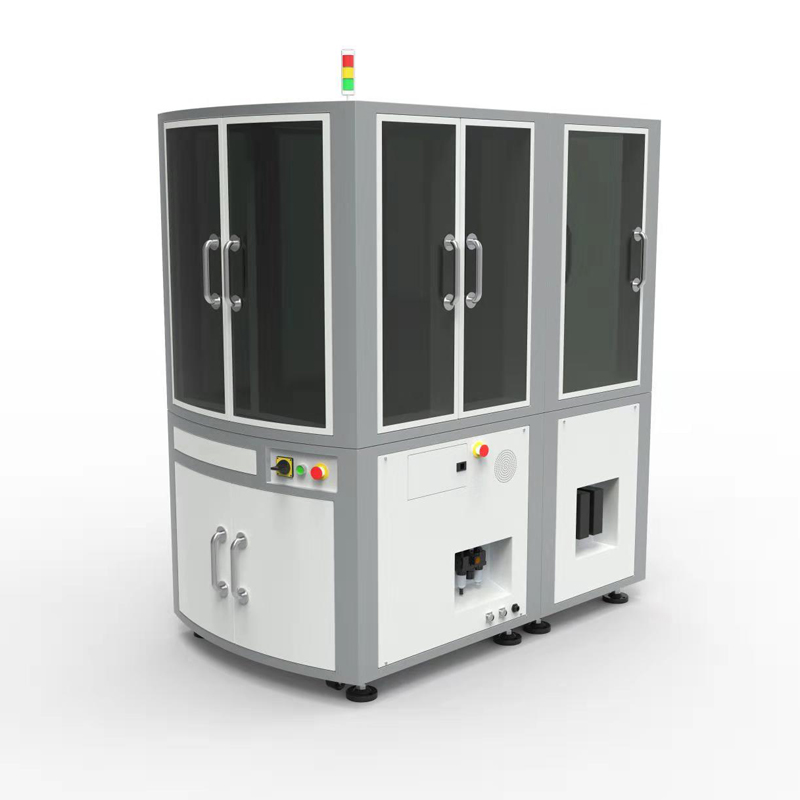

Two: equipment composition and main institutions

Overall composition: Size: 900*800*1850 mm

Model number :HL-301

1: Visual detection software

2: Industrial computers

3: Monitor 19 inches

4: Industrial camera: 4 sets, bottom detection plane scratch. Lateral detection of height and spiral teeth. Top detection screw front end damage. Backlight detects hole diameter

5: Industrial lenses: 4 sets of FA industrial cameras

6: Professional glass plate

7: solenoid valve

8: reducer

9: Vibration cabinet

10: Feeding equipment (vibration disk, direct vibration, controller).

Iii.1:3D stereogram of equipment appearance

Bottom surface detection mode

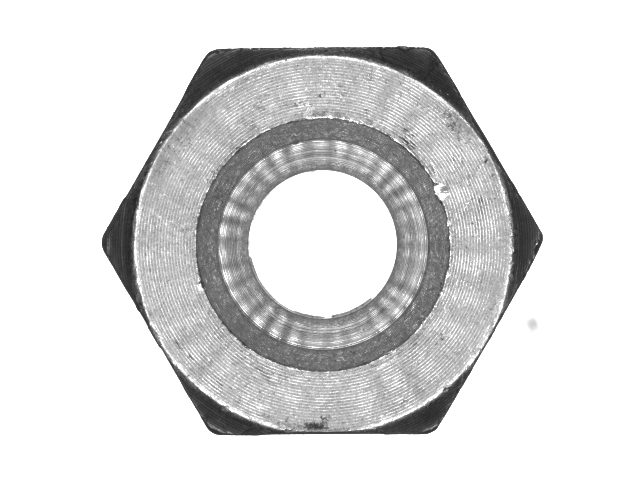

Original image of bottom detection effect:

Bottom detection mode

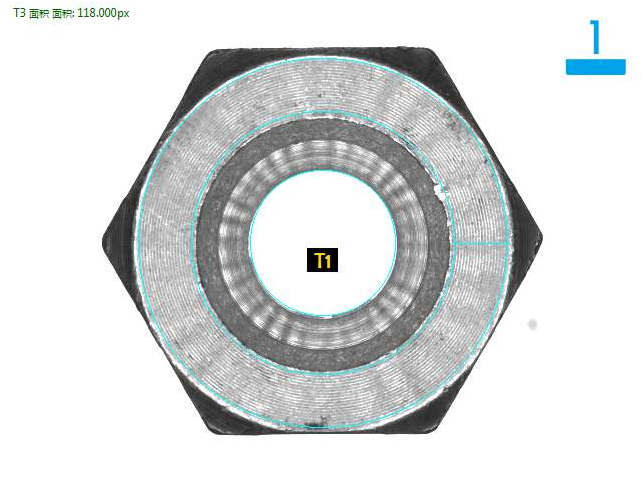

Analysis diagram of good product detected at the bottom :OK

Bottom detection mode

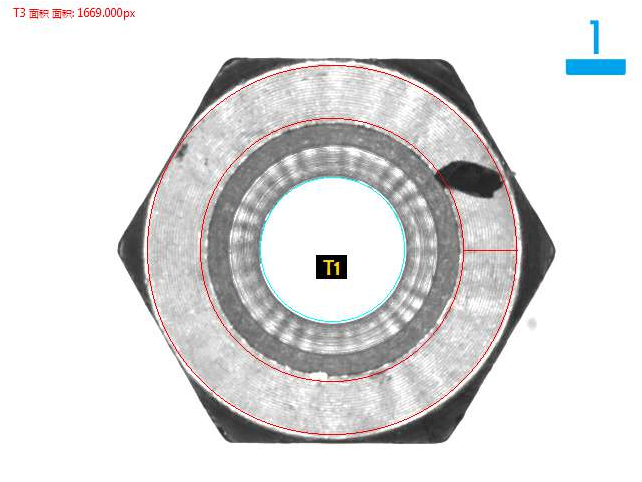

Analysis of oil pollution defective products detected at the bottom :NG

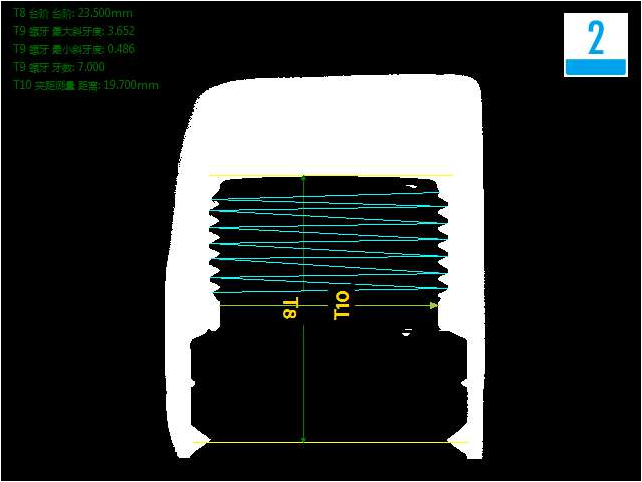

Side detection mode

Original image of side detection effect:

Side detection mode

Side detection of good product analysis diagram :OK

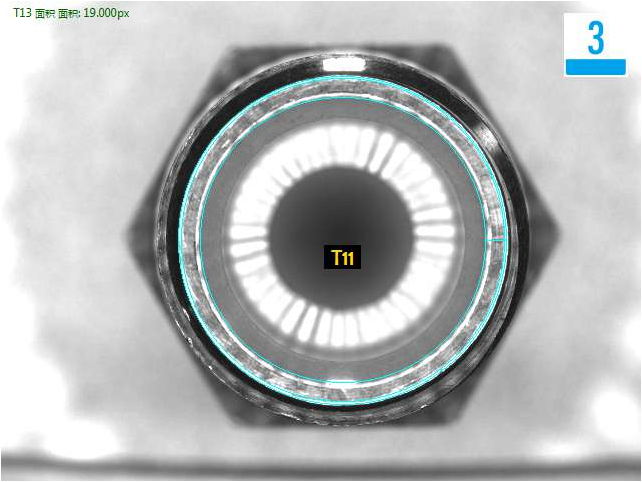

Top detection mode

Top detection good product analysis chart :OK

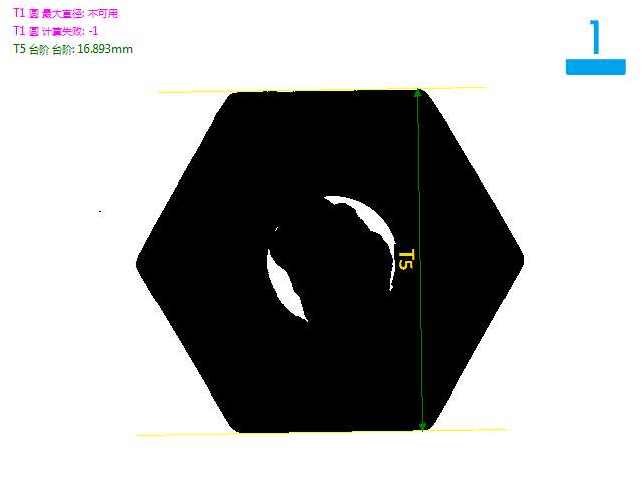

Top backlight detection mode

Good product analysis chart of backlight detection :OK

Top backlight detection mode

Analysis of defective products in backlight detection hole :NG

The above is the detection scheme of the joint screws.