Release time:2023-04-12 10:57:35 Viewed:0

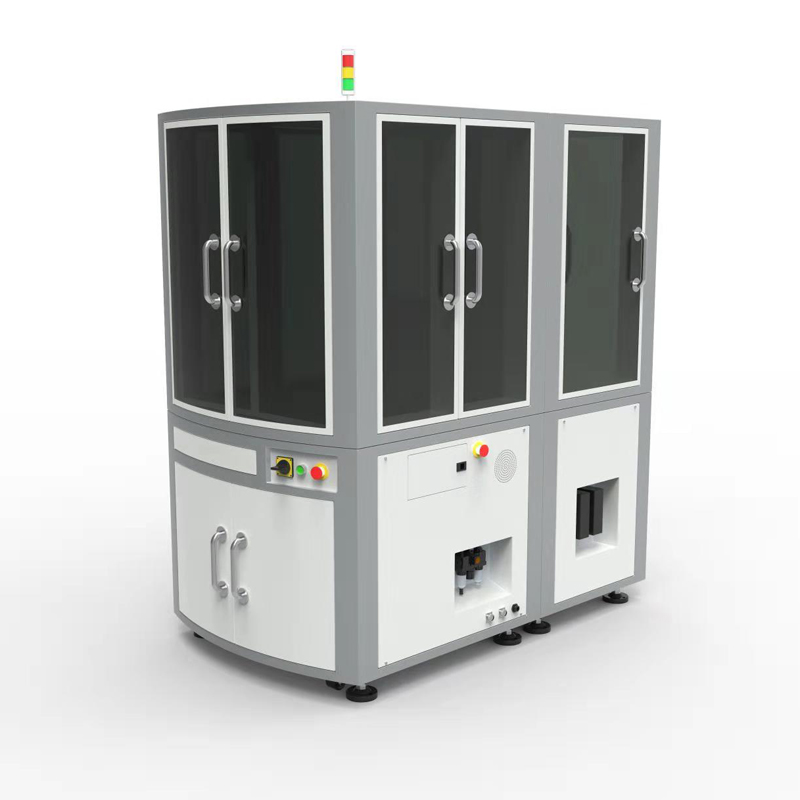

Screw optical image screening machine is formed by the visual detection principle of visible objects. The assembly line adopts the form of turntable, with good accuracy; For a wide range of screw manufacturing, screw sorting machine manufacturers, the use of speed control to ensure the precision control of pipeline products has a very good auxiliary role.

In order to reduce the complexity of detection calculation, the screw screening machine uses the photoelectric sensor to judge whether the screws have reached the certain position and detect the running condition of the pipeline, which ensures that the main control machine does not have to make continuous failure judgment, and can increase the working stability of the equipment.

Screw optical image screening machine using visible light object image acquisition and calculation, used for real-time parameter detection of screws, can directly determine whether the screw product defects, etc.

The screw screening machine monitor can directly display images related to screws, through the image detected by the nonconforming screws, give a signal to directly remove the nonconforming products from the line through the mechanical lifting device, at the same time can record the number of screws per shift and the number of nonconforming screws.

The above content is to introduce the working principle of the screw optical image screening machine, with the development and upgrading of domestic industry, all kinds of precision parts (such as car screws, electronic screws) need to fully check the appearance and size quality? Artificial long-term visual inspection, eye fatigue, resulting in low product detection efficiency and accuracy is not high, with machine vision instead of artificial vision can greatly improve the production efficiency and inspection accuracy, reduce customer complaints, reduce labor costs.