Release time:2024-01-23 10:29:54 Viewed:0

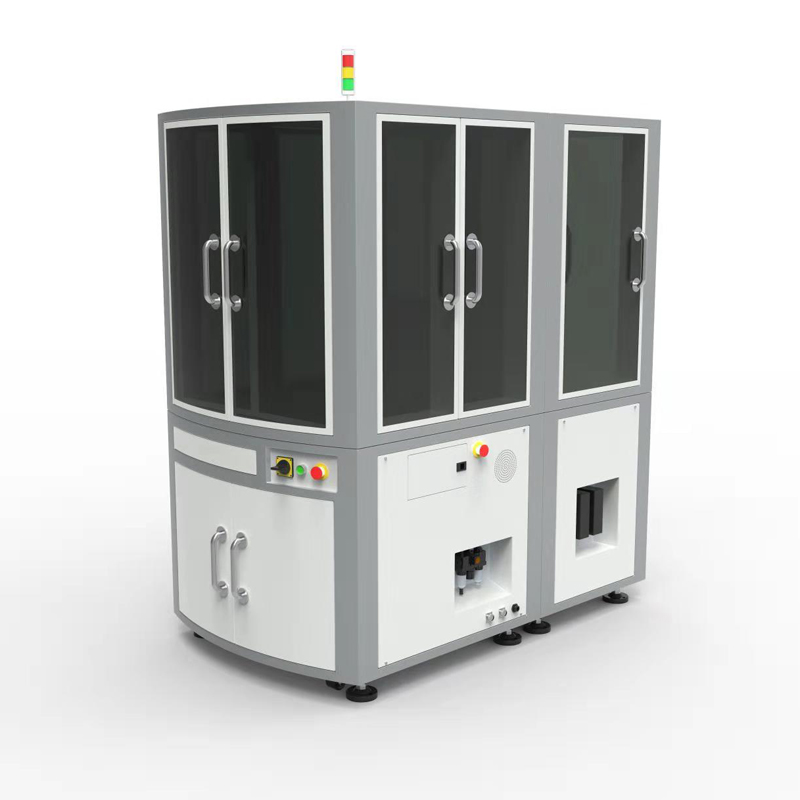

A vision inspection system, also known as machine vision system, is a technology that uses cameras, image processing, and algorithms to perform visual inspections and evaluations in various industries. The system is designed to mimic human vision and interpret the visual information captured by cameras to make decisions or provide analysis. Below HOLITEK presents 8 advantages of the vision inspection system.

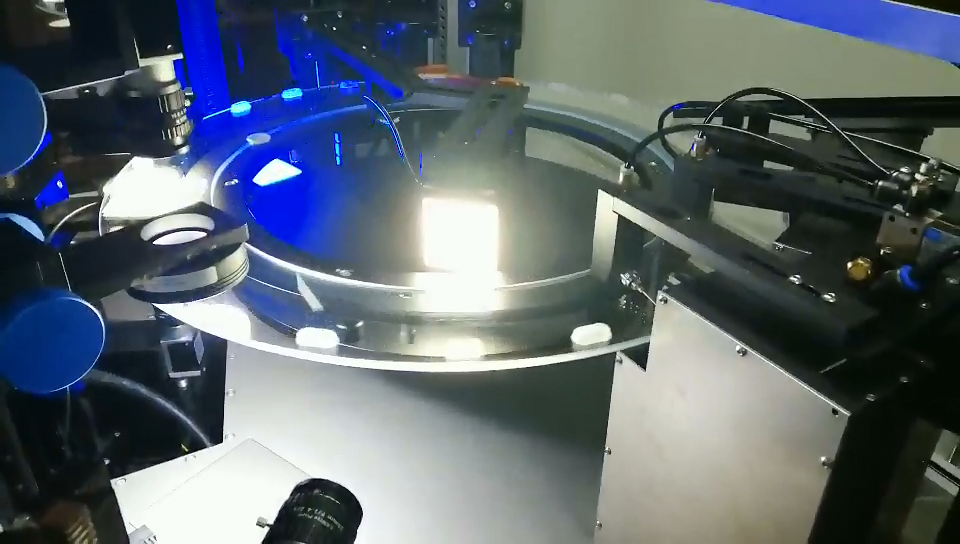

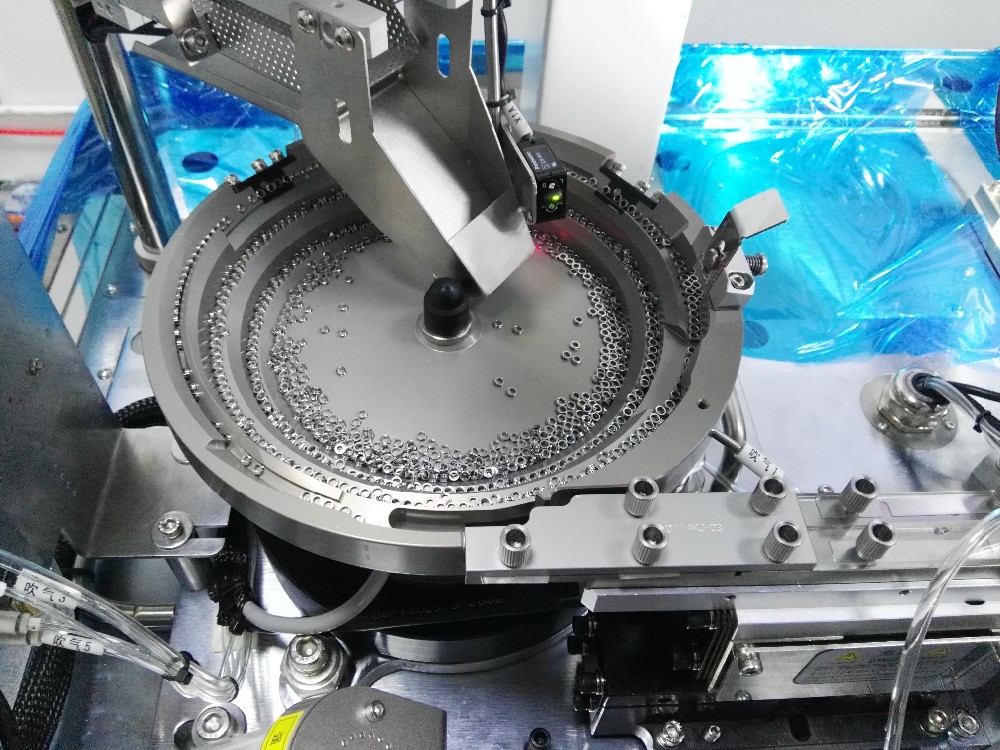

Vision inspection systems operate at high speeds, capable of processing and analyzing images in real-time. This enables rapid inspection of products on production lines, contributing to increased throughput and faster manufacturing processes. The high speed ensures that large volumes of items can be inspected quickly without compromising accuracy.

Unlike human inspectors, vision inspection systems maintain consistent levels of performance without being affected by factors such as fatigue, distractions, or variations in lighting conditions. This consistency leads to reliable and repeatable inspection results, reducing the likelihood of errors in quality control.

Vision inspection systems excel in precision and accuracy, providing detailed and reliable measurements for quality assessment. These systems can detect subtle defects, variations, or deviations that may be difficult for human eyes to identify. This high level of accuracy is crucial in industries where product quality is paramount.

Vision inspection systems can operate continuously, 24 hours a day, seven days a week. This constant monitoring ensures that every item passing through the production line is thoroughly inspected, contributing to early detection of defects and minimizing the risk of faulty products reaching the market.

While the initial investment in vision inspection systems may be significant, the long-term cost savings are substantial. These systems reduce the need for manual labor in inspection tasks, leading to lower labor costs. Additionally, by identifying defects early in the production process, manufacturers can avoid the costs associated with producing and shipping defective products.

Vision inspection systems can be programmed and configured to adapt to different products and inspection criteria. This flexibility makes them suitable for a wide range of industries and applications. As production processes evolve or new products are introduced, vision systems can be easily reconfigured to meet changing inspection requirements.

Vision inspection systems generate detailed data and reports related to the inspection process. This data logging capability is valuable for traceability, quality documentation, and process optimization. Manufacturers can analyze the data to identify trends, improve production processes, and ensure compliance with quality standards.

Vision inspection is a non-destructive testing method, meaning it doesn't damage or alter the products being inspected. This is particularly important in industries where preserving the integrity of the inspected items is crucial, such as in electronics or pharmaceutical manufacturing. Non-destructive inspection contributes to overall product reliability and longevity.

In conclusion, vision inspection systems play a vital role in modern manufacturing and quality control. Their ability to operate at high speeds, maintain consistency, provide precision, and adapt to various applications makes them indispensable tools for ensuring product quality and efficiency in diverse industries. The cost savings, continuous operation, and non-destructive nature of these systems further contribute to their widespread adoption across different sectors. As technology continues to advance, vision inspection systems are likely to become even more sophisticated, offering enhanced capabilities and contributing to further improvements in manufacturing processes.

HOLITEK is a factory specializing in the production and development of vision inspection machines. We undertake all kinds of difficult parts inspection projects and provide free inspection solutions to our customers. We welcome inquiries from all companies in need.

HOLITEK promises a lifetime warranty and permanent after-sales service.

Contact:Tim

Email: info@automaticrobot.net

Tel/Whatsapp/Wechat: +86-13172730751

Skype: timmachinecn@gmail.com

Website: www.automaticrobot.net