Release time:2023-04-26 09:15:07 Viewed:0

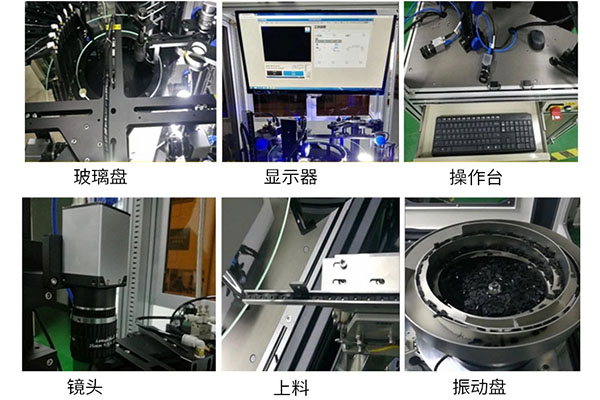

The role of optical screening machine is to replace manual inspection, and high accuracy, efficiency, high accuracy, an optical screening machine to replace 4-6 staff output, so it has been favored by the majority of processing factories!

With the development of electronic products, consumers want to choose perfect products when they buy electronic products. If there are scratches and bumps in the product, it will greatly discount the appearance of the product, and it will affect the quality of the product, reputation and business volume. At present, the detection of appearance defects of products generally relies on manual detection.

In the process of product production, manual inspection personnel must have a keen perception of the quality of a product to make an accurate judgment, so that defective products will not be sent to the hands of consumers. However, the current production speed is very fast, the products are more responsible, or the defects are more vague, it is difficult for the traditional labor to ensure the production volume, but also ensure the quality of the products.

Therefore, optical screening machine is used to replace manual inspection, to achieve faster, more accurate detection!

1, linear vibrating screen fully closed structure, good sealing, reduce dust pollution;

2, large processing capacity, simple structure, convenient maintenance, low energy consumption, less noise, long screen life.

3, can be used single or multi-layer, can reach seven layers, the screen frame is generally wooden structure, if the sieve hole is larger, the output is higher when the screen frame can be made of steel structure, if the screening corrosive materials, and the contact part of the material made of stainless steel.

4, the motor installation can be divided into lower vibration and side vibration, shock absorber installation can be divided into seat type and hanging type. It can also be specially designed according to user needs.

5, suitable for 0.074-15mm of any dry material screening, a large feeding size to no more than 20mm is appropriate.

Generally speaking, the principle of optical screening machine is through the precision car cutting high precision and high resolution fastener processing to get, like the function of the machine is to automatically calculate some parameters of the product, such as its internal aperture, plating poor and internal hole plug hole and so on, some gear data.

Moreover, automatic detection of thread is particularly important for the detection of gear and some screws. It can be seen that the application of optical image screening equipment in the processing industry is very extensive. The future market share of CCD optical screening machine will be better.