Release time:2023-04-27 13:08:41 Viewed:0

1. Test content and requirements

Detection of workpiece area:

Testing of cylindrical samples with overall height 4*2.5mm

Test contents:

1: The bottom edge of the detection of incision, hole, diameter

2: Side detection of total height

3: Top detection diameter, whether there is a hole

Note: The above test items, all need to be clearly visible under the image to detect

Detection efficiency: 200-400 pieces per minute (according to the sample feeding speed).

Division of work: subdivide the detection steps according to the detection content.

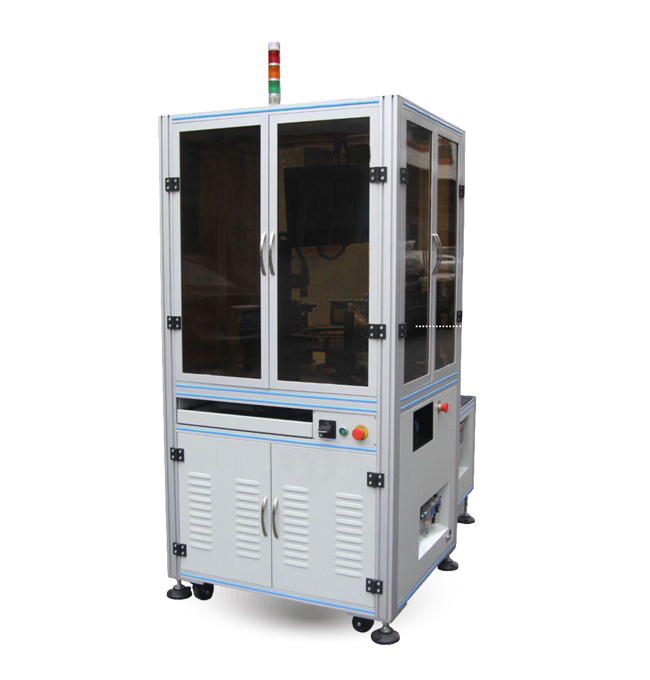

Two: equipment composition and main institutions

Overall composition: Size: 900*800*1850 mm

Model :HL-301

1: Visual detection software

2: Industrial computers

3: Monitor 19 inches

4: Industrial camera: 3 sets, bottom and top detection diameter, hole, edge incision. Side detection height

5: Industrial lenses: 3 sets of FA industrial cameras

6: Professional glass plate

7: solenoid valve

8: reducer

9: Vibration cabinet

10: Feeding equipment (vibration disk, direct vibration, controller).

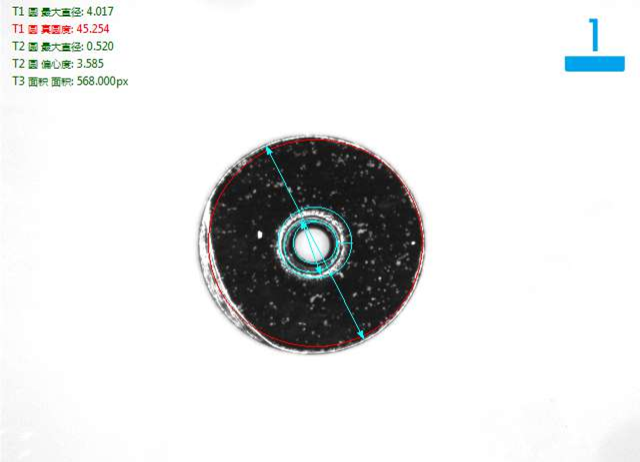

3:1 Bottom detection mode

Original image of bottom detection effect:

3:1 Bottom detection mode

Analysis diagram of good product detected at the bottom :OK

3:1 Bottom detection mode

Analysis of defective products on the bottom edge of detection :NG

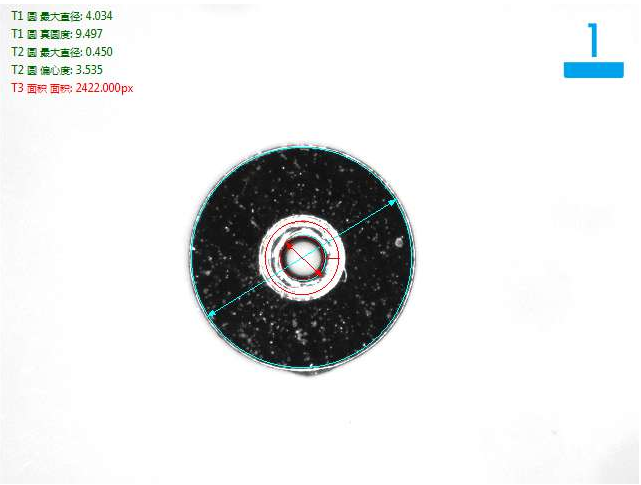

3:1 Bottom detection mode

Analysis of defective products with too large inner hole at the bottom :NG

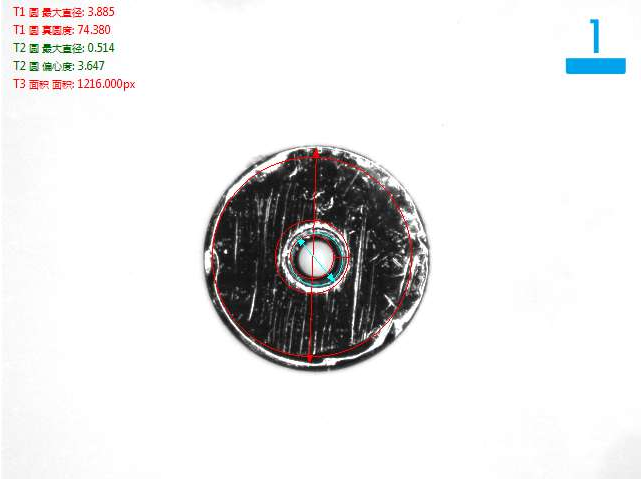

3:1 Bottom detection mode

Analysis of damaged and defective products detected at the bottom :NG

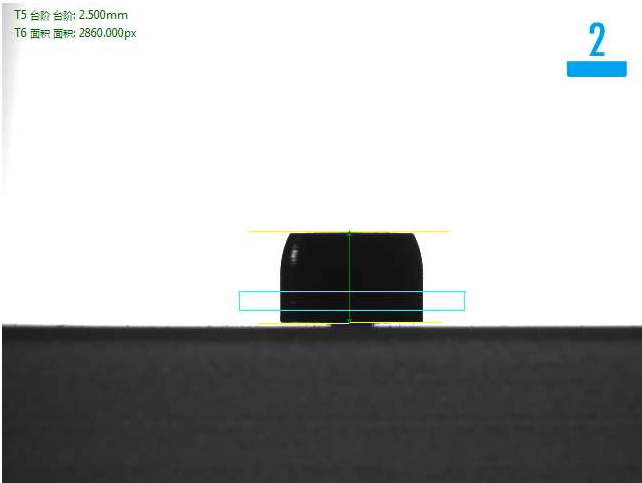

3:2 Side detection mode

Side detection of good product analysis diagram :OK

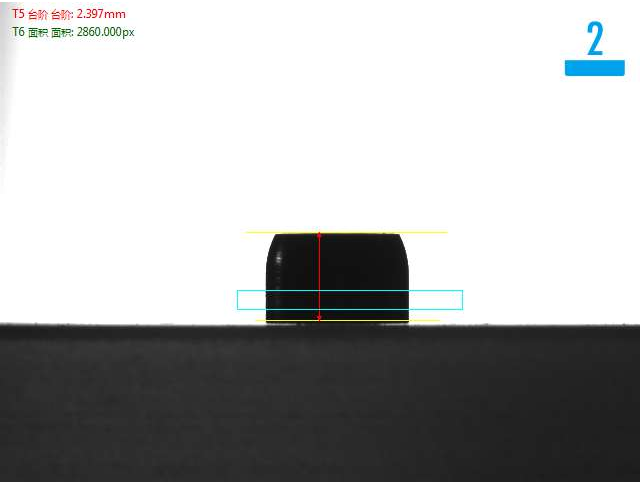

3:2 Side detection mode

Side detection of highly defective products analysis diagram :NG

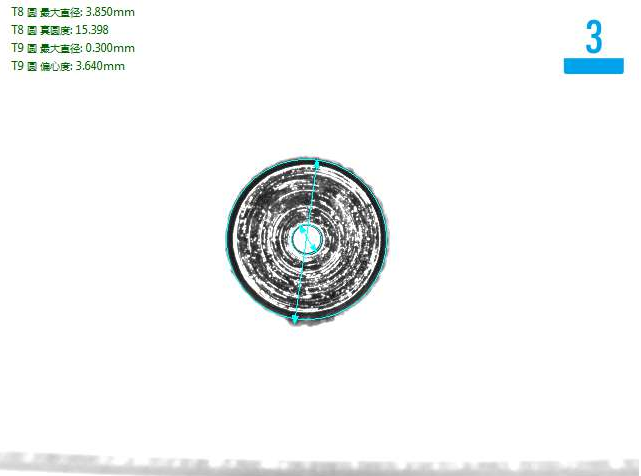

3:3 Top detection mode

Top detection good product analysis chart :OK

Iv. System Installation requirements:

Inspection space for equipment placement: The Sipple visual inspection system shall be installed separately at the side of the pipeline, and sufficient space shall be ensured to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic interference: Provide a place for equipment with less electronic interference.

Power supply: AC 220V, 50Hz, power consumption < 1KVA