Release time:2023-03-30 10:18:15 Viewed:0

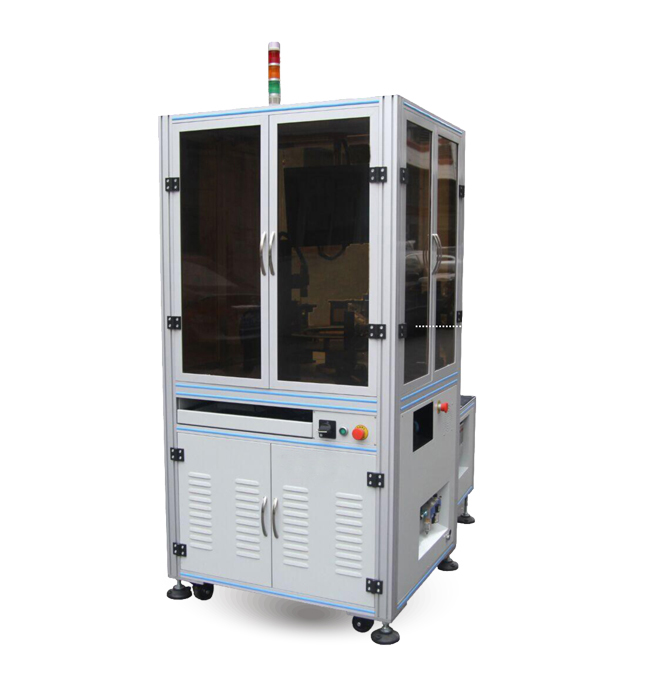

With the development of industry 4.0, more and more industrial manufacturing enterprises begin to use automatic intelligent equipment instead of manual repetitive work, such as visual inspection equipment, and establish intelligent factories with adaptability, resource efficiency and genetic engineering.

Visual inspection equipment is a new high-tech product. When it is delivered to customers, there is a visual inspection equipment acceptance process. Many customers have few opportunities to contact visual inspection equipment, and they are not clear about the acceptance process of visual inspection equipment, or even do not know that there is such an acceptance process.

Acceptance process of visual inspection equipment:

First, understand the equipment, hardware introduction

1: One-button switch, lighting button, three emergency stop buttons, light source controller and the position of the main box

2: Introduce the vibration disk, direct vibration and round vibration, direct vibration controller and round vibration controller, how to debug the controller (voltage and frequency)

3: Test samples from the round vibration feeding, to the direct vibration feed to the glass plate, after the dial wheel A dial wheel B, to the camera detection, camera photography after software analysis, judge the quality of the sample, to the bad product and good product of the air outlet, if there is no determination of the sample will directly run to the undetermined often blow outlet

4: Precautions in the modulation of direct vibration, direct vibration and the interval between the glass plate, dial wheel A, B and the interval between the glass plate

5: The role of photoelectric sensor and how to trigger, it will trigger when it is lower than 50,

6: When wiping the glass plate, pay attention not to press the glass plate, wipe with a dust-free cloth with alcohol, if the glass plate is uneven, you can manually press the two buckle the glass plate place (note is to press the glass plate), the glass so far

7: The final undetermined position of the baffle plate can not be scraped to the glass, and the glass interval is at least four layers of A4 paper thickness

8: alarm light. The alarm light is green in operation and red in alarm

9: The device will stop automatically in the case of low air pressure or glass plate jam

Two, how to operate the detection machine

1: operation steps;

a) One-button power on

b) Turn on the Siptek detection system

c) Select the style to be detected and select the corresponding configuration

d) Click Clear

e) Click Run

2: shutdown steps;

a) Click Run and wait for delay until the glass disk stops rotating

b) One-button shutdown

Three, understand the detection system

1: Configuration:

a) Different products can switch to different configurations. Under the condition that the light source and lens are not moved, the configurations can be switched directly when changing different products

2: System:

A) Positioning a) Positioning is the positioning of the product, correcting whether the product is in the middle of the camera

b) The positioning sequence is generally from dial wheel A to dial wheel B, through the photoelectric sensor induction product to camera 1, 2, 3, 4.... To bad product air outlet to good product air outlet

B) Reset positioning is used when the positioning is disorderly. After reset positioning, it needs to be repositioned

C) blow out open defective products is to set the first blow port into defective product discharge, open good products is to play a blow port set into good product discharge, the left mouse button click test not put, can test the blowing condition of two blow ports

D) Trigger CD to exclude samples that are too close to prevent misblowing

E) Trigger interval Minimum allowable sample time interval

F) Blow time Blow time of two blow ports

G) The vibrating disk power supply can be turned on or off without running

H) Ignore air pressure Ignore air pressure detection, only used in the absence of air contact

I) Calculate all the debugging purposes of the results, and it is recommended to disable