Release time:2023-03-22 15:36:06 Viewed:0

At present, most of the factories supporting the production of rubber O-ring for mechanical seal products are old equipment, backward industry, incomplete detection means, and product quality is difficult to be guaranteed. About 30% of the failure of the current mechanical seal in use is caused by the failure of the rubber O-ring. The main reason is that the quality inspection of rubber O-ring has not been paid attention to.

In the aspect of quality detection of rubber O-ring, most factories use calipers to measure the inner diameter, outer diameter and section. There are widespread shortcomings such as low efficiency of manual detection and large subjective judgment error. Because O-ring is flexible material, the measurement force will cause it can not be ignored deformation, this measurement method can not meet the accuracy requirements of mechanical seal parts.

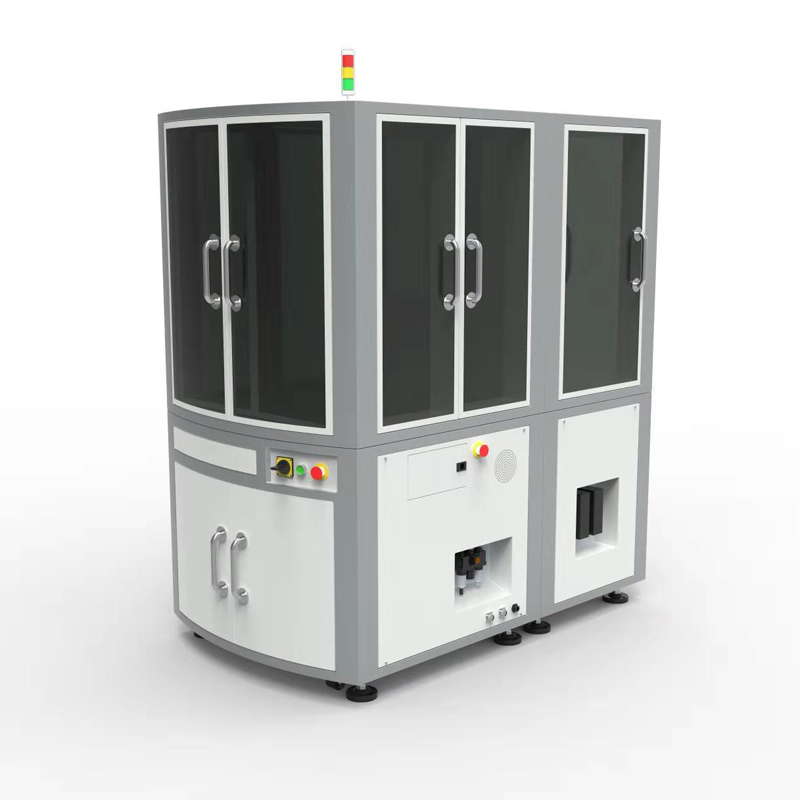

What equipment should be used to detect the rubber seal ring? Our visual inspection equipment has the following characteristics:

1, a wide range of detection: rubber parts, precision hardware, magnetic materials, electronic components and so on can be detected.

2. High detection efficiency: up to 400-1200/ min.

3. Accuracy: 99.9%.

4, automatic loading and unloading: one person can boot, up to 4-6 employees.