Release time:2023-03-22 09:45:38 Viewed:0

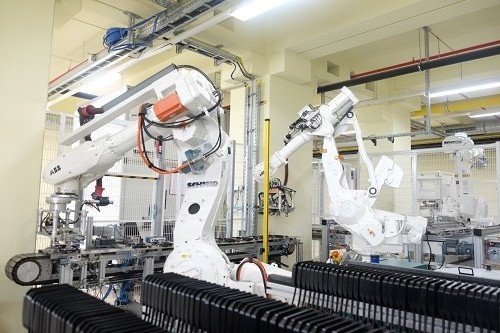

If the optical image screening system is further applied to the production control process, it can not only reduce the waste of raw materials, but also effectively control the production time when the production line is producing products. The appearance and size quality should be fully checked manually, and the long-term visual inspection should be carried out manually. Easy eye fatigue leads to low inspection efficiency and low accuracy of products. Replacing artificial vision with appearance screening machine can greatly improve production efficiency and inspection accuracy, and reduce labor cost.

An effective visual system helps you improve efficiency and performance by eliminating defects, verifying assembly, and tracking and collecting information at every stage of the production process. Therefore, after processing is complete, the nuts need to be inspected to pick out non-conforming products. This is usually done manually and automatically testing the line brand. It is time-consuming and laborious to test the thread of nut one by one with thread tap, and it directly increases the production cost of the enterprise by automatically testing the production line plant.

At this time, we need to use O-ring visual inspection equipment, which can detect the appearance and size defects of the sealing ring in all aspects. In the face of such complex detection requirements, if we only rely on manual detection, the effect and efficiency of detection can not adapt to the higher and higher quality requirements and more and more expensive labor costs, and the machine vision system match, Visual accuracy measurement is also related to vi system, and visual identification system online monitoring is a key application of visual accuracy measurement in machine vision system.

Then machine vision is easy to realize information integration, is the basic technology to achieve computer integrated manufacturing, so machine vision detection also helps to protect the reputation of the brand and the interests of the manufacturer, through machine vision can detect whether the position of the cork is correct, whether it is tight, whether there are defects, etc., 3, drug bubble cap detection, because of the strict specifications of the pharmaceutical industry, The quality of pharmaceutical packaging is also increasingly demanding. When the drug granules are packed into the bubble cap, it is necessary to check whether the drug granules in the bubble cap are intact and meet the requirements.

The traditional human eye detection has a fatal defect, that is, the subjectivity brought by emotion, the detection results will change according to the mood of the workers, the machine does not have joy, sadness and happiness, the detection results are natural, accurate and reliable, machine vision test specific application examples: 1, test whether there are defects in tablet drugs; 2. Check the display screen to verify the correctness of ICONS or the existence of pixels; 3, test touch screen, machine vision technology to measure the backlight contrast level, especially high-end products and innovative products market is huge, in the next few years, design links, strategic areas, 3c applications and traditional industrial applications have become the key investment areas of the integrated circuit industry, in addition, China has become an important global demand market for integrated circuits, it can be seen that, Visual inspection equipment is not only the only way for enterprises to transform and upgrade to intelligent manufacturing, but also an effective shortcut for enterprises to save labor resources, improve production efficiency and bring considerable benefits! .